ผู้จัดจำหน่าย RTD คุณภาพสูง มาตรฐานสากล

RTD SENSORS

RTD แบ่งออกเป็น

-

-

- ชนิด : PT100, PT1000 Class A, B, DIN1/10 (Single – 2,3,4 wires / Double -4,6 wire)

- ปลอกป้องกัน RTD : 1.6mm., 3.2mm., 4.8mm., 6mm., 6.4mm., 8mm (เดี่ยว/คู่)

- ท่อ : SS316L ขนาดเส้นผ่าศูนย์กลางท่อ : 3mm. – 16mm.

-

Applications

– Power & Utilities –Turbines / Bearing Temperature

-Oil & Gas application -Spares / replacement assembly

-Chemical & petrochemical -Pumps, compressors & diesel engines

-Water, waste-water treatment -Cement Industries

-Bearing temperature measurement -Air & flue gas applications

-Nuclear applications -Refinery & Petrochemicals Plants

-Autoclave applications -Stator winding of motors & generator

-Steel & Power applications –Pharmaceutical, Food & Beverages

-Surface measurement in refractoy vessels

Resistance Temperature Detectors (RTDs) Generally, electrical resistance of any metallic conductor varies according to temperature changes. The sensor for measurement of temperature by utilizing this phenomenon is called “Resistance Thermometer” or “RTD” and can measure temperature more precisely than other temperature sensors.

Its Features

Resistance Temperature Detectors for industrial applications have the following features.

1. Good sensitivity

2. Excellent stability and reproducibility

3. High accuracy

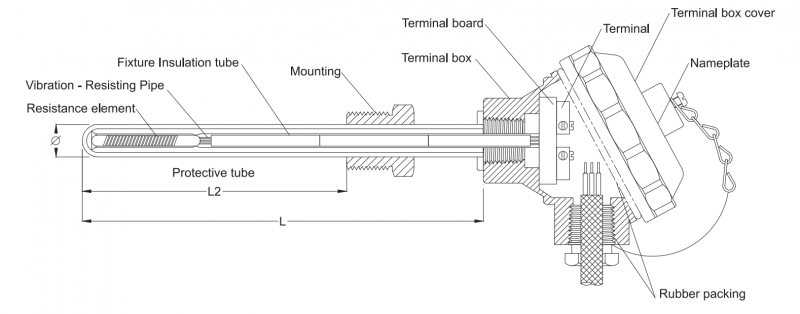

Structure and Measuring Methods

Structure:

Metal wire that changes its electric resistance to changes in temperature are utilized is called “Resistance Wire” This resistance wire, normally of platinum, is used to manufacture a temperature sensor called “Resistance

Temperature Detectors (RTDs)Element”.Generally speaking, RTD is composed of RTD element, lead wires, protection tube and terminals.

Measure Methods:

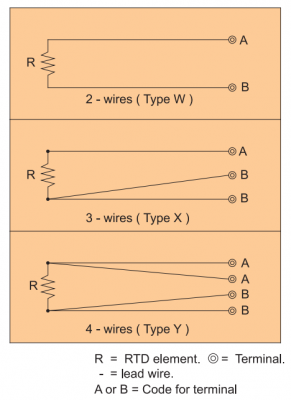

2-Wires Connection: Type W

RTD element is connected to respective two wire leads. Although it is less expensive than other types, it is not recommendable for high precision measurement of temperature because it is susceptible to lead resistance and produces error.

3-Wires Connection: Type X

One end of RTD element is connected to two wire leads and the other end connected to single lead to eliminate the effect from lead resistance. This type is most widely used as reliable method in industrial applications.

4-Wires Connection: Type Y

RTD element is connected to respective two wire leads to remove the effect from lead resistance. This connection cancels lead resistance effect and is especially recommendable for high precision measurement of temperature but somewhat expensive than other types.

RTD element is connected to respective two wire leads to remove the effect from lead resistance. This connection cancels lead resistance effect and is especially recommendable for high precision measurement of temperature but somewhat expensive than other types.

Precautions in practical Applications

Selection of proper RTD suitable for the application is the most important factor. For precision measurement of temperature, consideration should be given to selection of RTD element, protection tube, structure and fitting (location) according to the respective resistance to heat, corrosion, mechanical shock and other environmental conditions.

Resistance Temperature Detectors (RTDs)

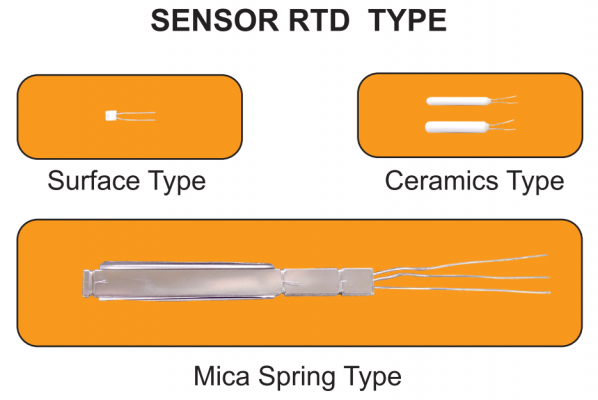

Construction

Temperature can be measured by utilizing a pure metal wire’s resistance, which increases at afixed rate with increasing temperature. Platinum resistance elements used most commonly for this purpose consist of a pure platinum resistance wire wound around a mica strip or other material. Some elements are formed by winding the resistance wire around a glass or mica core frame and sealing the assembly in a hard glass or ceramic tube. The element is attached with lead wires (two or three) and put in a protecting tube, with a terminal box and mounting fittings connected.

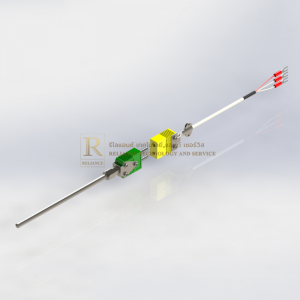

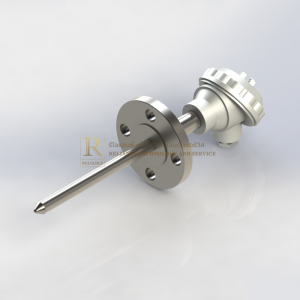

RTDs

RTD RTS1

RTDs

RTD RTS2

RTDs

RTD RTS3

RTDs

RTD RTS4

RTDs

RTD RTS5

RTDs

RTD RTS6

RTDs

RTD RTS7

RTDs

RTD RTS8

RTDs

RTD RTS9

RTDs

RTD RTS10

RTDs

RTD RTS11

RTDs

RTD RTS12

RTDs

RTD RTS13

RTDs

RTD RTS14

RTDs

RTD RTS15

RTDs

RTD RTS16

RTDs

RTD RTS17

RTDs

RTD RTS18

RTDs

RTD RTS19

RTDs

RTD RTS20

RTDs

RTD RTS21

RTDs

RTD RTS22

RTDs

RTD RTS23

RTDs

RTD RTS24

RTDs

RTD RTS25

RTDs

RTD RTS26

RTDs

RTD RTS27

RTDs

RTD RTS28

RTDs

RTD RTS29

RTDs

RTD RTS30

RTDs

RTD RTS31

RTDs

RTD RTS33

RTDs

RTD RTS34

RTDs

RTD RTS35

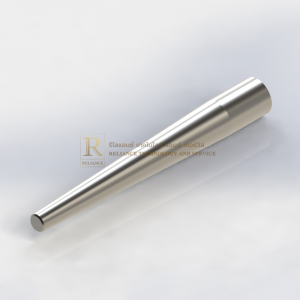

RTDs

THERMOWELL RTS-TW1

RTDs

THERMOWELL RTS-TW2

RTDs

THERMOWELL RTS-TW3

RTDs

THERMOWELL RTS-TW4

RTDs

THERMOWELL RTS-TW5

RTDs